The largest conventional rail project in the UK

The Transpennine main line runs for 70 miles (113 km) across the North of England between York and Manchester. Passing through 23 stations, including the major cities of Leeds and Huddersfield, the line runs over 285 bridges and viaducts, 29 level crossings and 6 miles (10 km) of tunnels as it passes under the Pennine Hills West of Leeds. It is currently the largest conventional rail project in the UK.

The Transpennine Route Upgrade (TRU) is a vital component of the UK Government’s ‘levelling up’ ambitions aiming to reduce the discrepancy between wealth and opportunity in different parts of the UK. TRU aims to decrease journey times and increase reliability, capacity and safety.

Improving connectivity to and between Northern towns and cities will boost the regional economy, offer individuals employment opportunities and employers a wider talent pool to draw upon, as well as transform the train passenger experience by decreasing journey times and increasing reliability, capacity and safety.

TRU East is the alliance (Network Rail, VolkerRail, Siemens, Murphy, SYSTRA) set up to deliver the works between Leeds and York. Passing from feasibility to option selection to design, the delivery of TRU East has been grouped into two phases of work.

Overcoming the design challenges

The design challenge is significant due to the sheer number of civil structures, such as bridges and culverts: 120 on the TRU East section. Each of these must all be assessed to work out whether they can take the different loadings of heavier and faster trains, then necessary reinforcement or alterations are designed where required.

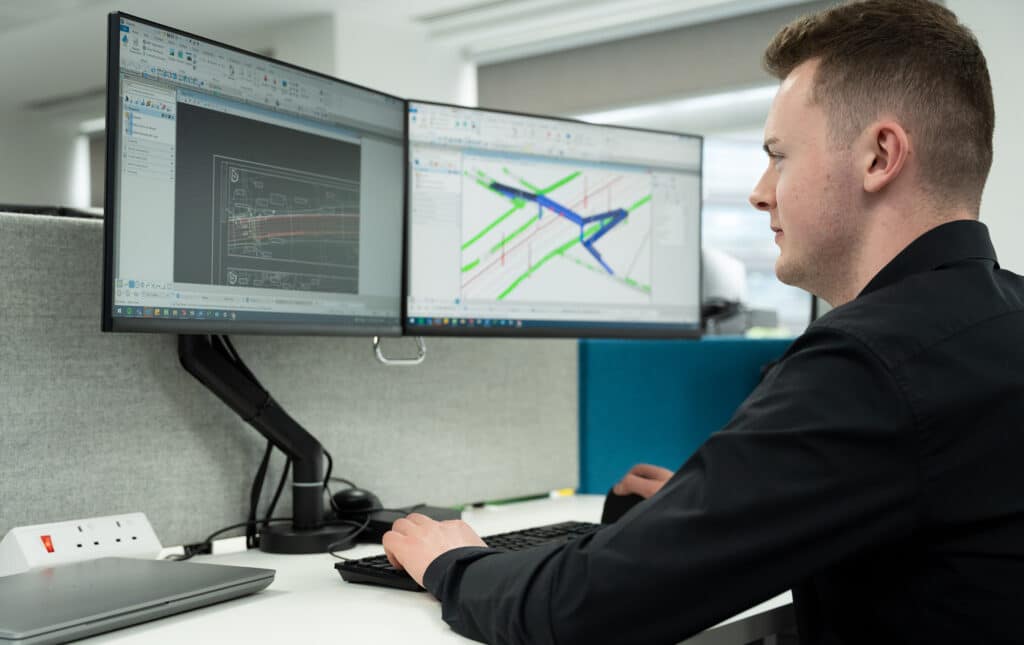

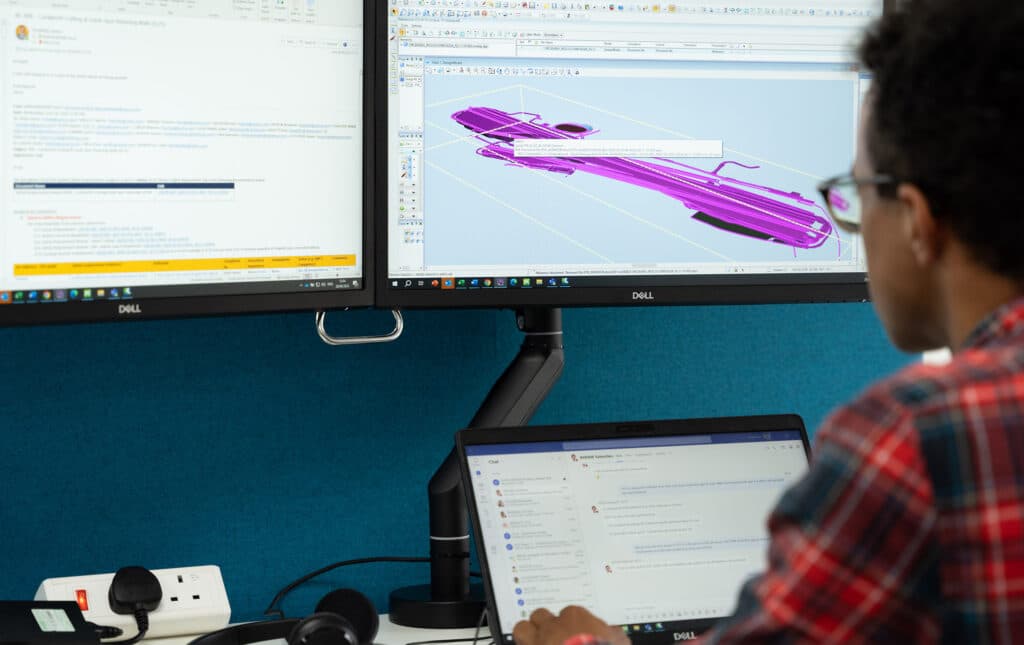

SYSTRA is undertaking multiple design roles across the project: Principal Designer; BIM management and coordination; survey management and topographical surveys; design integration and coordination; design of overhead lines, track, power supplies, highways, drainage, civil engineering, bridges, level crossings; system safety; and human factors.

IMPROVING RIDEABILITY

Enabling works for first phase of TRU East between York and Church Fenton began in 2019. Masts for electrification were erected, under track crossings were completed, ballast was cleaned and some track was realigned to improve rideability.

Commissioning of this section is due in 2025.

Replacing level crossings and improving safety

One of the most important safety improvements that the TRU will deliver is the replacement of level crossings with road bridges and footbridges. Level crossings are the most dangerous elements of the line, so removing them will reduce the risk of incidents. In planning and designing the new bridges, it will be vital to liaise closely with local residents and other stakeholders to make sure that issues such as access and location are optimised and understood. For instance, Diversity Impact Assessments ensure that ramps are included alongside steps where needed.

Improve train timetable for Leeds Station’s 20m annual passengers

Our work included a timetable assessment of ‘utilisation of points’ and the associated impact on the reliability of train services at Leeds Station, used by almost 20 million passengers a year and one of the busiest stations in the whole of the UK. We concluded that additional tracks were required at Leeds Station West End and that the operational layout for Leeds Station East End should be changed to best suit the railway configuration further east. This would minimise disruption and conflict between services and rolling stock access.

A collaborative ethos generating ideas and trust

SYSTRA is physically co-located with our Alliance partners to enable a ‘one team’ approach and where remote working has been necessary, or where input from specialists from the wider SYSTRA business is needed, the team has a tranche of digital tools, chosen to help preserve the collaborative ethos.

This allows for flexibility and agility, which is necessary because scopes and outcomes for the programme have and will change over time due to political and other considerations. For instance we were called on to undertake a study to assess the use of European Train Control System (ETCS) in-cab signalling which would remove line-side signals and allow safer and higher capacity operation.

Adopting lean principles to increase efficiency

The delivery strategy has included the formation of a Value and Creations Team to eliminate waste, and adopt lean principles in all areas of the Programme. With the assistance of the Alliance members, the team have collated over 260 ideas to increase efficiency, reduce waste and ultimately save money across all areas of the Project. Each idea is assessed and, if deemed suitable, developed into a business case to gain funding for additional work streams and site investigations.

A DIGITAL APPROACH

TRU East is deploying some new in-house SYSTRA digital tools.

A carbon calculator, which allows material and product choices to be evaluated on their carbon emissions as design is underway, is being used on this project for the first time in the UK.

Rail Systems Integration

Our specialist teams have defined a systems approach to delivery of TRUe, from the definition of a requirements framework through to efficient management of verification and validation. The Systems Engineering and Assurance team also lead the system integration and assurance activities, including system safety and Human Factors, inclusive of demonstrating compliance to regulations such as CSM-RA and RIR.

- services

Systems Approach

Read more sur Systems ApproachInnovation: SafebyBIM identifying hazards

One of our team has been inspired to develop a useful safety tool SafebyBIM to visually identify potential hazards. We have been piloting this new system which uses a BIM model, making it easier to identify and eliminate hazards. The development of the SafebyBIM system has been funded through SYSTRA’s SPARK entrepreneur R&D programme.

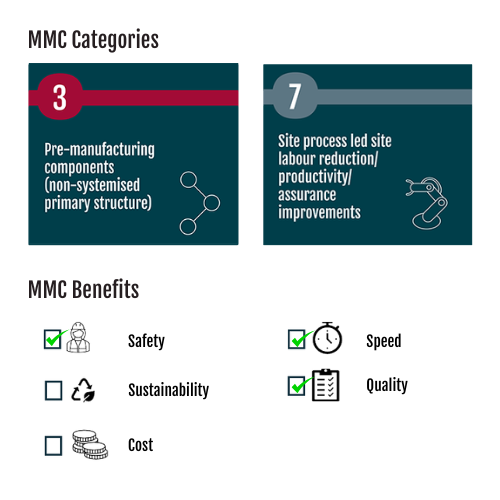

Modern methods of construction applied in the Transpennine Route Upgrade – NOC/23 Culvert Replacement project

As part of the TRU East alliance, we proposed a tunnelling solution that minimised the impact on the existing line and reduced waste that would have been generated with a typical top-down construction approach. Precast concrete culvert units were pushed under the active line resulting in zero accidents and increasing the net biodiversity on the project.

We’d love to help with your next project

Our Markets

Read more sur Our Markets

Our Services

Read more sur Our Services

- services

Tunnel Engineering

Read more sur Tunnel Engineering

- services

Geotechnical Design & Ground Engineering

Read more sur Geotechnical Design & Ground Engineering

- services

Railway Track Engineering & P-Way

Read more sur Railway Track Engineering & P-Way

- services

Systems Assurance

Read more sur Systems Assurance

- services

Systems Engineering & Integration

Read more sur Systems Engineering & Integration

- services

Australia

Australia  Brazil

Brazil  Canada

Canada  Chile

Chile  China

China  Columbia

Columbia  Denmark

Denmark  Egypt

Egypt  France

France  India

India  Indonesia

Indonesia  Ireland

Ireland  Italy

Italy  Malaysia

Malaysia  New Zealand

New Zealand  Norway

Norway  Panama

Panama  Peru

Peru  Poland

Poland  Portugal

Portugal  Saudi Arabia

Saudi Arabia  Singapore

Singapore  South Korea

South Korea  Spain

Spain  Sweden

Sweden  Taiwan

Taiwan  Thailand

Thailand  Türkiye

Türkiye  United States

United States  Vietnam

Vietnam