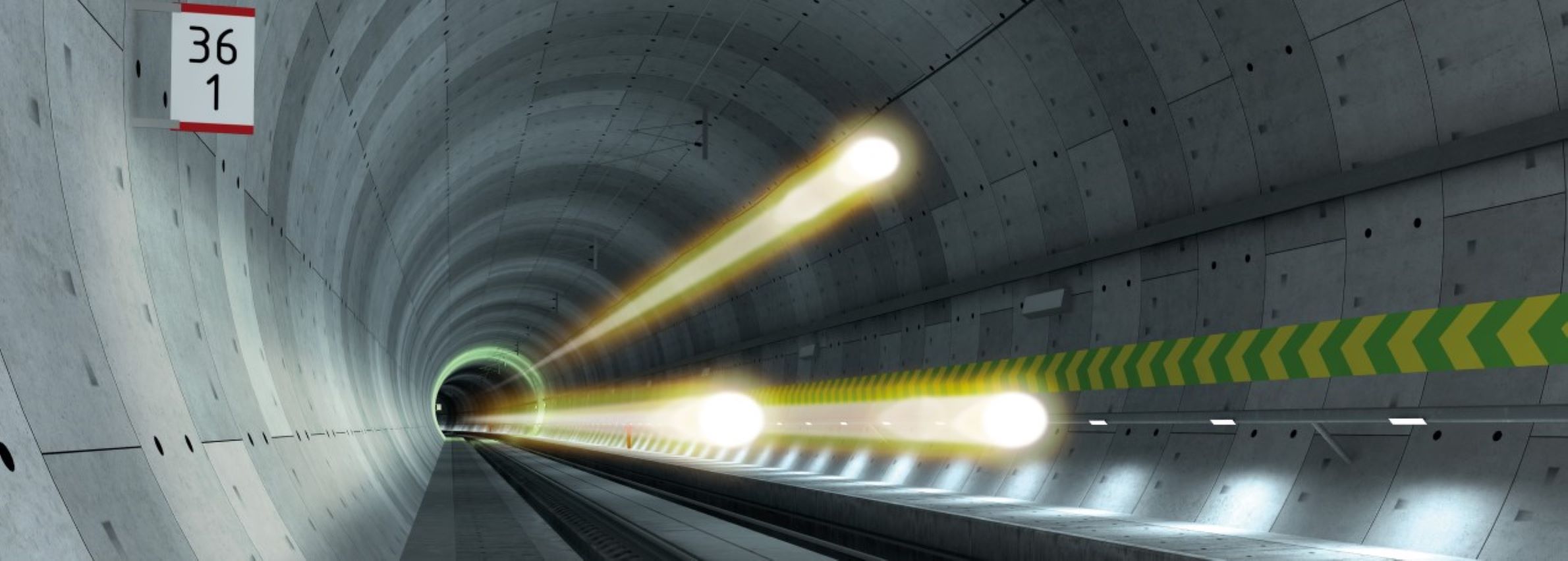

The Brenner Base Tunnel is one of the longest rail tunnels currently under construction in the world. By 2032, it will enable the Austrian and Italian networks to interconnect under the Alps, with mixed conventional and high-speed connections for freight and passengers.

In total, for a final structure 64km long from end to end between Innsbruck in Austria and Fortezza in Italy, 230km of tunnels will have to be bored and built under the Alpine rock. Once completed, the Brenner Base Tunnel will be the backbone of the Munich – Verona line.

A LONG-TERM PROJECT FOR SYSTRA

SYSTRA’s teams in Italy have been contributing to the construction of the tunnel since the initial design studies in 2005. Since 2016, they have worked on Lot Mules 2-3 providing a wide range of engineering services demanding a high level of technical and professional skills including detailed design of civil works, TBM selection, General Contractor assistance during the tender phase and during construction, BIM modelling, MEP design and implementation of value engineering optimisation measures.

In 2024, BBT SE, the contracting authority, awarded a three-year contract to the consortium led by Italferr, with SYSTRA and two Austrian design offices (ILF Consulting Engineers and EUT Engineering) as co-contractors, for engineering services and rail equipment for the Brenner Base Tunnel. The consortium will be responsible for the final design of equipment and railway systems.

Together, we will support BBT SE at every stage of the project, with the added challenge of the tunnel’s cross-border dimension. Each system of railway equipment will have to comply with the technical regulations in force in Austria and Italy and guarantee full interoperability with European standards.

SAFETY FIRST

In addition to its gigantic size, the Brenner tunnel is characterised by the requirement for numerous safety measures, inspired by those deployed in the Channel Tunnel. For example, if a fire broke out in the tunnel, trains would not have to stop immediately but would have to go to the nearest emergency station.

Passengers would be evacuated to the service tunnel via one of the communication branches, while the air would be kept cool by the excess pressure in the main tunnels. Evacuation doors are installed every 90 metres so that passengers can take refuge, wait for help in the service tunnel, or exit through one of the access tunnels.

A STRATEGIC AND SUSTAINABLE PROJECT FOR EUROPE

This cross-border tunnel is part of the trans-European TEN-T network, which envisages the creation of a high-capacity high-speed network to encourage the transport of people and goods by rail across the continent. The aim is to reduce CO2 emissions and promote more sustainable mobility in Europe.

Brazil

Brazil  Canada

Canada  Chile

Chile  China

China  Columbia

Columbia  Denmark

Denmark  Egypt

Egypt  France

France  India

India  Indonesia

Indonesia  Ireland

Ireland  Italy

Italy  Malaysia

Malaysia  Norway

Norway  New Zealand

New Zealand  Panama

Panama  Peru

Peru  Poland

Poland  Portugal

Portugal  Saudi Arabia

Saudi Arabia  Singapore

Singapore  South Korea

South Korea  Spain

Spain  Sweden

Sweden  Taiwan

Taiwan  Thailand

Thailand  Türkiye

Türkiye  United Kingdom

United Kingdom  United States

United States  Vietnam

Vietnam