a benchmark in terms of safety and sustainability

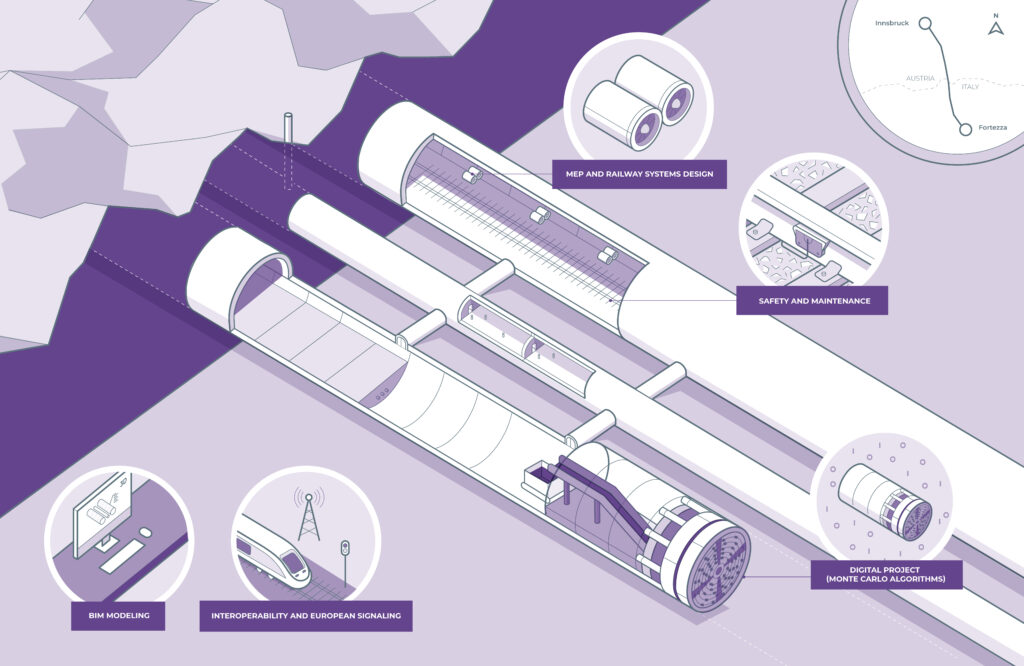

When it opens in 2032, the Brenner Base Tunnel (BBT), which will link Austria and Italy, is set to become the backbone of southern Europe’s rail network. Stretching 64 kilometres under the Alps between Innsbruck (Austria) and Fortezza (Italy), this historic infrastructure project aims to improve passenger and freight transport while advancing the sustainable mobility objectives of the Trans-European Transport Network (TEN-T). The latter is a high-speed, high-capacity network that will transport people and goods across the European continent. SYSTRA has played a leading role in this particularly innovative project for two decades. Spotlight on this extraordinary project.

*MEP (mechanical, electrical and plumbing)

2

single-track tunnels

55

kilometres of base tunnel

64

kilometres including Innsbruck Bypass

2025

completion of big infrastructure works

2028

expected commissioning

What is a ‘base’ tunnel?

Base tunnels are constructed at the foot of mountains, allowing the rail line to remain as direct as possible. This approach minimises gradients and effectively removes the barrier posed by the mountain, enabling trains to travel as if they were on flat land.

Nevertheless, tunnelling through the mountain from its base results in a much longer tunnel compared to building one closer to the summit, where the mountain is narrower. Reaching higher elevations requires steep ascents, which not only elevate energy usage but also increase journey duration.

Key features

goods trains

Passenger trains

- Passenger and freight rail tunnel

- Contractor and Client (Lot Mules 2-3): Brennero Tunnel Construction

- Length: 55km of base tunnel; 64km (incl.Innsbruck Bypass)

- Two single-track tunnels

- ERTMS Level 2 signalling and GSM-R Ridership:

- Completion of mechanised excavation (three TBMs) in May 2025 (Lot Mules 2-3)

- Commissioning of the tunnel expected in 2028 (Lot Mules 2-3)

SYSTRA present for two decades

SYSTRA has been contributing to the BBT project since 2005, starting with the preliminary design. Since 2016, the SYSTRA Italy teams have worked on Lot Mules 2-3 providing a wide range of engineering services demanding a high level of technical and professional skills including detailed design of civil works, TBM selection, General Contractor assistance during the tender phase and during construction, BIM modelling, MEP (mechanical, electrical and plumbing) design and implementation of value engineering optimisation measures.

In 2024, BBT SE, the contracting authority, awarded a three-year contract to the consortium led by Italferr, with SYSTRA and two Austrian design offices (ILF Consulting Engineers and EUT Engineering) as co-contractors, for engineering services and rail equipment for the Brenner Base Tunnel. The consortium is responsible for the final design of equipment and railway systems for the tunnel.

Together, we are supporting BBT SE at every stage of the project, with the added challenge of the tunnel’s cross-border dimension. Each system of railway equipment will have to comply with the technical regulations in force in Austria and Italy and guarantee full interoperability with European standards.

“Being part of the joint venture responsible for the detailed design of railway equipment in the Brenner Base Tunnel means contributing to one of Europe’s most ambitious infrastructure projects. Our combined expertise in underground structures and transport systems, driven by ongoing innovation, is helping to set new standards for safety and sustainability in European mobility.”

Erica Calatozzo, Chief Executive Officer, SYSTRA Italy

Innovation at the heart of the project

The Brenner Base Tunnel serves as a prime illustration of modern advances in infrastructure planning and construction, prioritising durability, safety, and operational performance. Designed with a projected service life of 200 years, the tunnel sets a new standard for sustainability, exceeding what is typically expected from similar large-scale projects. The adoption of pioneering methods—such as innovative construction materials, automated transport technologies, and continuous real-time monitoring—represents a substantial improvement over conventional construction approaches.

Notable features like prefabricated segmental linings and an advanced monitoring system not only increase the tunnel’s resilience but also provide accurate, ongoing oversight of its structural health.

In addition, innovations such as the integrated drainage pipe cleaning system and the carefully considered layout of the exploratory tunnel simplify routine maintenance activities, allowing these to be performed without interrupting rail movements; this ensures optimal long-term operation.

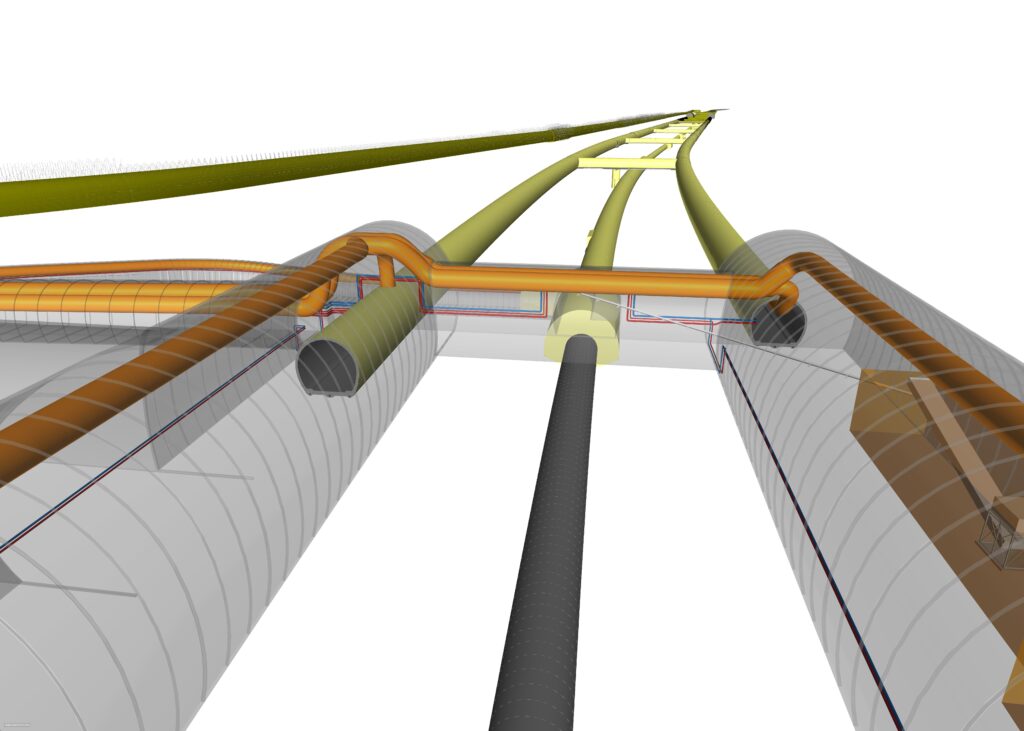

The extensive use of Building Information Modelling (BIM) across all project stages provides a robust management framework and maximises operational transparency, giving all parties direct access to critical information from initial planning through to maintenance. Altogether, this comprehensive strategy highlights the crucial role of well-conceived infrastructure in driving economic growth and improving international links.

Detailed analyses allowed the selection of the most suitable TBM machines, considering the severe Alpine conditions.

Advanced numerical analyses (2D and 3D models) led to improvements in both design and construction allowing us to consider the big challenges that a long and deep tunnel like BBT poses. Specifically, The Trens Emergency Stop (one of three emergency stops foreseen for safety reasons and the only one located on the Italian side) posed a challenge due to the very complex lay-out of several interconnected tunnels.

The integration of innovative solutions is being made at every stage of the project:

- Enhanced safety: new evacuation standards, emergency air overpressure systems, advanced monitoring, and cross-border interoperability,

- Inter-European engineering: cross-border adaptation and full interoperability with all European control and signalling systems,

- Collaborative process: an international engineering joint venture that brings together French, Italian, and Austrian expertise for a robust yet flexible design.

Focus on Innovative Solutions

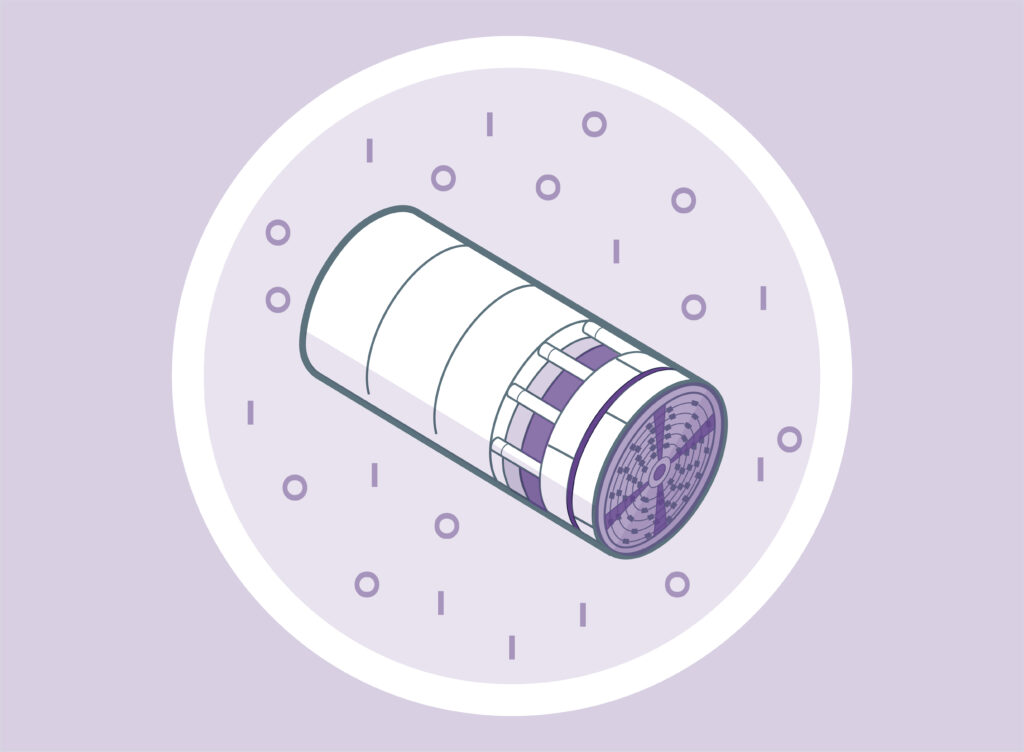

Tunnel

To address the challenge of selecting tunnel boring machines (TBMs) suitable for extremely variable Alpine rock conditions, SYSTRA developed the Digital Project Hard Rock Tool. This digital solution utilises Monte Carlo algorithms* for advanced statistical risk evaluation, ensuring the most reliable tunnelling methods are chosen.

*A Monte Carlo algorithm is a method that uses randomness to solve problems that might be too complicated to handle directly in a deterministic way.

Innovative materials research

A major challenge was the development of collapsible backfilling*. Expanded clay was identified as the most promising solution, even though its mechanical characteristics were insufficiently explored at the time. SYSTRA led a research project to develop, validate, and implement this innovative approach tailored for the tunnel’s demanding environment.

*Collapsible backfilling is a tunnel construction practice involving highly flowable, easily compacted material used to fill voids behind linings or supports, ensuring safety in the lining under high rock pressure together no future settlement and structural stability.

MEP and safety systems

The tunnel’s electrical, ventilation, fire detection, and access control systems combine the latest technologies, are modelled in BIM, and designed to meet Austrian, Italian, and European requirements for interoperability, safety, and resilience.

A BENCHMARK FOR FUTURE INFRASTRUCTURE

The Brenner Base Tunnel is considered one of the most important infrastructure projects of the century. Advances are incorporated into every stage of the project, from planning to operation, enabling the project team to meet constantly evolving modern requirements even during the construction process. The focus is on cutting-edge technologies that improve the tunnel’s efficiency, safety, sustainability and maintainability. As a result, the Brenner Base Tunnel is not only an iconic engineering feat, but also a benchmark for future infrastructure developments, demonstrating a commitment to long-term sustainability.

See Also other Innovation stories

Innovation Story #1: the T10 tramway in Lyon

Backed by SYSTRA’s expertise, the new T10 tramway links Vénissieux, Saint-Fons and Lyon, providing a sustainable and inclusive transport solution for the Lyon metropolitan area. Find out how this emblematic project illustrates SYSTRA’s commitment to efficient, environmentally-friendly urban mobility.

Australia

Australia  Brazil

Brazil  Canada

Canada  Chile

Chile  China

China  Columbia

Columbia  Denmark

Denmark  Egypt

Egypt  France

France  India

India  Indonesia

Indonesia  Ireland

Ireland  Italy

Italy  Malaysia

Malaysia  New Zealand

New Zealand  Norway

Norway  Panama

Panama  Peru

Peru  Poland

Poland  Portugal

Portugal  Saudi Arabia

Saudi Arabia  Singapore

Singapore  South Korea

South Korea  Spain

Spain  Sweden

Sweden  Taiwan

Taiwan  Thailand

Thailand  Türkiye

Türkiye  United Kingdom

United Kingdom  United States

United States  Vietnam

Vietnam