PROJECT DESCRIPTION

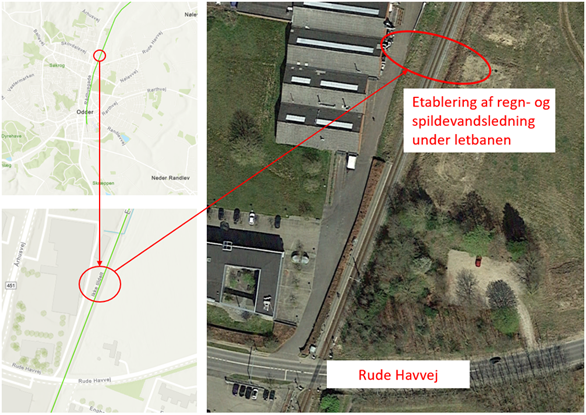

At SAMN Forsyning, the road was narrow due to a sewerage renovation project in Odder, necessitating multiple crossings of the light rail tracks via directional drilling. Therefore, CSM (Common Safety Method) competencies combined with broad professional understanding were necessary. The CSM part of the project was particularly challenged because the Light Rail had a shelf project ready for a possible future track expansion. SYSTRA took over responsibility for part of a larger contract to ensure clear allocation of responsibilities. The construction work was carried out in partnership.

risk assessment

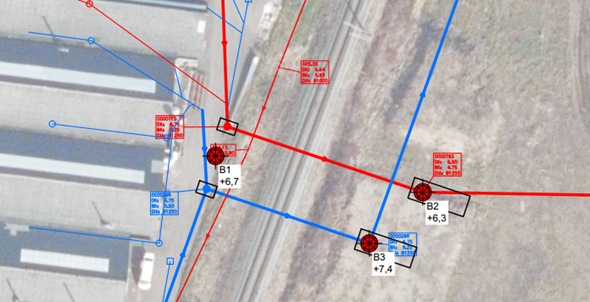

The task involved identifying the risks in the project, how they could be managed, and what could be considered for modification in the project. With SYSTRA’s extensive experience in CSM processes, soil conditions, and the importance of directional drillings for tracks in operation, it was decided that three directional drillings would be reduced to two, and some aspects of the existing conditions needed to be addressed differently in case the track expansion was delayed.

The design of construction groups was projected based on the current soil conditions, including a high water table, in close dialogue with the executing contractor. The focus was on achieving the most optimal solution for the current site, considering the machinery available to the contractor, while also minimizing the project’s impact on the light rail.

The schedule, traffic diversions, and other details were agreed upon and coordinated with stakeholders in the area.

THE PROJECT INCLUDES:

- Groundwater lowering with monitoring

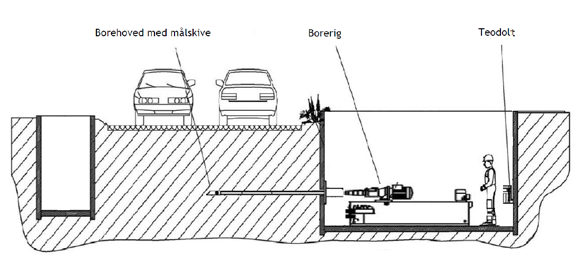

- Establishment of construction and receiving groups for drilling using the pilot pipe method with a 50-ton pressing force

- Reaming with 2×30 m Ø350 steel pipe casing followed by pulling through of media pipes

- Controlled injection with volume-resistant cement-based mortar, ensuring there are no voids between the soil and the casing pipe, preventing measurable deformations of the track due to reaming

- Tracking of the track’s position with a tracking roller before and after the directional drillings

Australia

Australia  Brazil

Brazil  Canada

Canada  Chile

Chile  China

China  Columbia

Columbia  Egypt

Egypt  France

France  India

India  Indonesia

Indonesia  Ireland

Ireland  Italy

Italy  Malaysia

Malaysia  New Zealand

New Zealand  Norway

Norway  Panama

Panama  Peru

Peru  Poland

Poland  Portugal

Portugal  Saudi Arabia

Saudi Arabia  Singapore

Singapore  South Korea

South Korea  Spain

Spain  Sweden

Sweden  Taiwan

Taiwan  Thailand

Thailand  Türkiye

Türkiye  United Kingdom

United Kingdom  United States

United States  Vietnam

Vietnam