Amitava Das, Assistant Vice President of Architecture of Railway Infra Vertical SYSTRA India, talks about the evolution of metro and railway building projects and India’s potential to become the global exporter of railway technology.

How is India addressing the environmental sustainability of metro and railway expansion in major cities and tackling the challenges of large-scale infrastructure development?

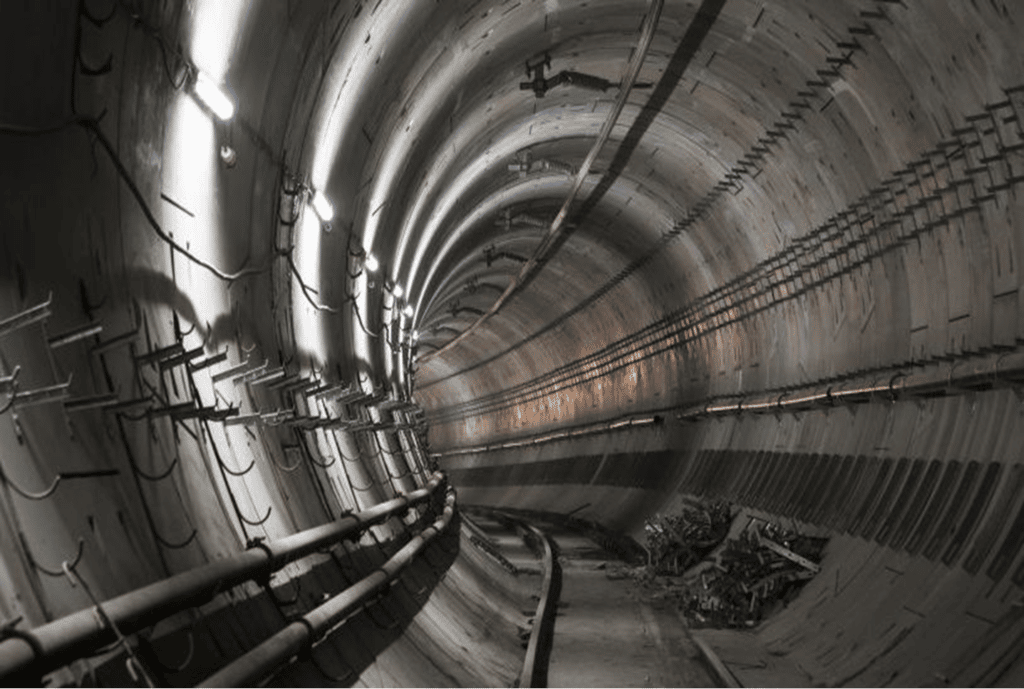

India aims to become a developed country by 2047 and achieve net zero carbon emissions by 2070, which requires sustainable infrastructure development and environmental friendliness. A key aspect of this development is the expansion of metro and railway lines in major cities and regions to address the negative impacts of personal vehicles, such as traffic congestion and increased pollution.

The National Metro Rail Policy of 2017 encourages cities with populations of 20 lakhs or more to adopt mass rapid transit systems. Metro rail has experienced significant growth in India recently and is expected to double or triple in the coming years. The demand for metro rail is urgent to meet daily mobility requirements in cities. Additionally, metro rail reduces costs and travel time, improving the city’s competitiveness.

How can India enhance its exports in the global rail market, and what steps should be taken for this?

The Indian Railways is undertaking various upgrades, such as modernising existing tracks, producing new locomotives and train sets for high-speed inter-city travel, laying high-speed railway lines, and deploying onboard train protection systems. To support these efforts, the ‘Make in India’ initiative has encouraged companies to invest and manufacture in India, leading to collaboration opportunities between domestic and global players to enhance indigenous consumption and exports of Indian railway products.

Although India has a large indigenous railway sector manufacturing and an established railway ecosystem, it has yet to become a major exporter of railway products. India mainly exports railway rolling stock to neighbouring countries such as Myanmar, Bangladesh, Sri Lanka, and Australia. With only a 1 percent share of the global railway export market (under HS Code 86), the government must play a larger role in the railway sector to enhance the export share. The approach to attracting global MNCs and foreign companies to set up manufacturing units in India needs to change.

India can increase its exports in the global rail market by adopting a focused approach, inducting new technologies, and collaborating with large rolling stock companies. Additionally, a special vehicle organisation can consolidate the in-house manufacturing expertise of the Indian Railways to look for technical collaborations with leading railway equipment manufacturers and effectively scout the world market for avenues where Indian-manufactured railway products can penetrate. Finally, India’s SME manufacturing ecosystem must keep pace with these developments.

What initiatives are government agencies and private companies considering to boost development in this sector?

According to a report by FICCI and EY titled ‘Railway Sector: A Key Driver for ‘Make in India’ Program’, government agencies are developing lighter coaches with higher carrying capacity, speed potential, locomotive life, and improved safety features. These coaches will be 1005 manufactured using a new procurement method at the diesel locomotive factory in Marhowra and the electric locomotive factory in Madhepura, demonstrating how global firms can be attracted to set up manufacturing units in India.

By indigenously sourcing many sub- components for these higher horsepower locomotives, Indian suppliers can move up the technology chain and integrate into the global supply chain of private global manufacturing companies. Initially, the manufacturing facilities will focus on fulfilling mandatory orders from Indian Railways, after which they can shift their focus to meet export demands.

What about the investments made and required to achieve efficiency while meeting project deadlines?

Meeting strict project deadlines while fulfilling other project requirements can be challenging. In order to ensure consistent adherence to project deadlines, it is necessary to invest in or implement the following measures: thorough project and construction planning, adoption of an Agile approach, hiring or augmenting the right team or individuals, utilisation of collaborative project management information system tools or software, and planning for the unexpected or potential risks. These investments and measures can significantly improve the efficiency and effectiveness of project management, ultimately resulting in the timely delivery of projects.

What procedures are in place to ensure workers’ and project safety?

In any project or construction site, there are potential dangers that could threaten workers’ safety. To minimise these risks, organisations can adopt certain safety measures, such as regular training for workers on the proper use of tools and equipment. It is also essential to assess the site to identify potential hazards and take necessary precautions. Wearing protective uniforms and equipment can significantly improve safety and follow safety protocols before visiting the site. Installing signages can remind workers about the risks and requirements, and steps should be established and followed to report faulty equipment or procedures. Organisations can sensitise workers to potential dangers by implementing these safety measures and ensuring a safe and secure project or construction site.

Read the article here

Australia

Australia  Brazil

Brazil  Canada

Canada  China

China  Denmark

Denmark  France

France  Indonesia

Indonesia  Ireland

Ireland  Italy

Italy  Malaysia

Malaysia  New Zealand

New Zealand  Norway

Norway  Poland

Poland  Saudi Arabia

Saudi Arabia  South Korea

South Korea  Sweden

Sweden  United Kingdom

United Kingdom  United States

United States  Singapore

Singapore  Taiwan

Taiwan  Thailand

Thailand  Vietnam

Vietnam